All About Steel Infill Panels

Table of ContentsMore About Steel Infill Panels8 Simple Techniques For Steel Infill PanelsExcitement About Steel Infill PanelsSome Ideas on Steel Infill Panels You Need To Know

Infill walls are typically installed on website as private components that are pre-cut to size however they can be pre-fabricated as large panels with the cladding currently connected. The exact same elements may be made use of for interior separating walls, but below the primary issues are fire resistance and also acoustic insulation instead of resistance to.loading. A nominal inner pressure is made use of in the design of internal dividing wall surfaces. @&&h2@ [top]

Kinds of

The Main Principles Of Steel Infill Panels

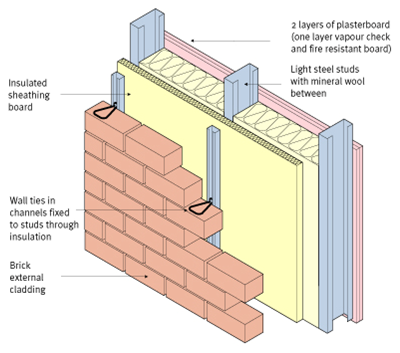

Light steel mounted infill walls @&&/h3@ In multi-storey mounted building and construction, it is currently typical method to utilize light steel infill walls to create a fast completely dry envelope to support the outside cladding. The exact same type of building might be utilized as separating or compartment wall surfaces in between different components of the building. The use of light steel infill walls might be used to steel or concrete framed construction. Lightweight, speed as well as ease of installation are very important constructional advantages that have caused the fast boost in operation of this kind of building.

The light steel components made use of in infill wall surfaces contains C sections and U areas of.

The smart Trick of Steel Infill Panels That Nobody is Discussing

75 to 150 mm depth that are chilly roll-formed from galvanized steel strip of 1. steel infill panels. 2 mm density specified to BS EN 10346. The galvanizing( zinc layer) gives exceptional resilience. The C sections are positioned at 400 or 600mm spacing as well as sets of C sections may be made use of next to huge openings. Wall surface panels can be pre-fabricated as storey-high systems or, more often, are site set up from C sections that are provided cut-to-length. The 2nd approach is commonly the only solution in restoration applications where resistances in the original building need to be suited. Site constructed light steel wall surfaces in a steel mounted structure Pre-fabricated light steel infill wall panels in a steel mounted building Infill wall surfaces are composed of a lower' track' affixed to the floor as well as a leading' track' connected to the underside of the floor above. This activity is important in concrete frameworks, where 2 to try this out 3 mm shortening of the concrete framework per flooring can happen over time as well as typical architectural activities. The upright C areas are developed to span 2. 4 to 5m between floorings, and also to resist wind loads or other lots in flexing. The straight C areas over and also listed below the home windows transfer lots back to the upright C areas. One or 2 layers of' fireproof' plasterboard( satisfying BS EN 520, Kind F) to the inner face provide for up to 90 mins fire resistance to the light steel infill wall surface. @&&h3@ [leading] Light steel separating wall surfaces @&&/h3@ Pre-fabricated light steel wall surface panels Light steel separating wall surfaces make use of similar components to.

light steel infill walls and are utilized to give acoustic splitting up and fire compartmentation between tenancies or unique components of the building. For both of these functions, double layers wall surfaces are generally specified in order to accomplish the required Get the facts acoustic attenuation in between tenancies. The structural loading for internal wall surfaces is fairly low and also is usually taken into consideration to represent an interior pressure of 0. 5 k, N/m . The C sections are usually much thinner than in exterior walls( typically 0. steel infill panels. 9mm thick )and acquire some benefit of the stiffness of the plasterboard chosen the exterior. Dividers are not required to have.

acoustic or fire features as well as so are single fallen leave walls comprising C areas of 55 to.

The Ultimate Guide To Steel Infill Panels

90mm depth, relying on the wall height, with solitary layers of plasterboard on each side. @&&h3@ [top] Masonry infill wall surfaces @ & &/ h3 @. Walls created from clay bricks or cinder block are the standard type of infill wall construction. Nonetheless, making use of block-work infill walls has lowered in recent years since it is an unpleasant and time consuming site procedure, and also calls for a huge amount of materials handling. From a design perspective, strengthening messages are needed beside large window openings, as the masonry is not sufficiently solid to stand up to the high neighborhood wind loads next to these openings. @&&h3@ [top] Concrete infill walls @&&/h3@ Pre-cast concrete infill wall surface panels Concrete infill walls are typically in the type of big precast concrete panels that are storey high as well as often of a width dictated by the column spacing. These large panels may be top put up or bottom supported. They commonly bear onto the floor slab

using a boot plan, and also are click resources bolted back to the structure on the level over or listed below. Indispensable panels may be outfitted in various other materials( normally concrete panels are outfitted in rock). Panel weights of around 300kg/m are normal, with panel widths of between 3 and 9m as well as elevation of 3. 2m. The maximum size of panel is limited by transportation factors to consider and crane lifting capability( both on site and at the concrete jobs). 15 to 20 tonnes are normal optimum weights of precast concrete panels. @&&h3@ [top]. Wood mounted infill wall surfaces @&&/h3@ Lumber infill wall surfaces utilize typical hardwood sections of 90.

as well as 140mm depth to period 2. 4 to 3. 6m between floorings and also are comparable in form to light steel infill walls. Timber areas are cut to length as well as are put at 400 mm or 600 mm spacing. The negative aspect of timber in contrast to steel is that it is not as solid and also it is not feasible to utilize it in high wall surfaces or in wall surfaces with large openings. @&&h2@ [top] Advantages of light steel infill and also separating wall surfaces @&&/h2@